TriPlex™, LLC was formed in 2011 when our team uncovered a new anodizing process that is far more powerful than anything used in the previous 89 years.

Anodizing is an electrolytic passivation process that increases the thickness of the surface oxide layer on metal. The process is called “anodizing” because the part to be treated forms the anode electrode of an electrical circuit. By increasing the surface oxide layer, anodizing increases corrosion and wear resistance, and provides better adhesion for paint primers and glues. Anodization changes both the microscopic texture of the surface and the crystal structure of the surface metal.

TriPlex allows companies to replace heavier metals with TriPlex processed aluminum, resulting in reduced weight, improved durability, lower costs, and better protection from caustic elements.

TriPlex can be applied as a hard anodize (.0018 – .0022), or as a decorative anodize (.0004 – .0006).

TriPlex Chem Film, an anodic film, can also be used as both a hardening and decorative treatment.

TriPlex Chem Film (hexavalent or trivalent) can take temperatures up to 350°F with a failure only after 312 hours in salt spray (ASTM-B-117).

TriPlex anodize or Chem Film can be applied to any aluminum material.

Dyed and undyed results still exceed MIL-A-8625 testing requirements, while non-dyed TriPlex™ products are the most durable.

The patented TriPlex process comes out of the simple idea of putting a ‘candy coating’ of stainless steel on aluminum and then anodizing it, creating a final product that is acid resistant, impact resistant, abrasion resistant and corrosion resistant but still retaining the superior heat-dissipation qualities of aluminum. Under testing, the TriPlex process has been proven to be vastly superior to anything else on the market today.

New Ideas, New Processes and New Ways of Doing Business Keep U.S. Manufacturing on the Cutting Edge

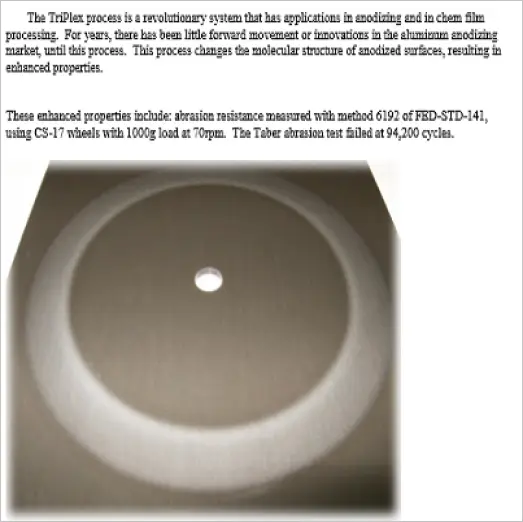

The TriPlex™ process is a revolutionary system that has applications in anodizing and in Chemfilm processing.

© 2021 Lights Camera Action. All rights Reserved. Designed And Developed By Ogrelogic. Privacy Policy